|

Baoding Haorui Machinery Manufacturing Co., Ltd.

|

Chinese Low Price Plastic Recycling Line

| Payment Terms: | T/T,L/C,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

HAORUI plastic company mainly manufactures various plastic recycling machines.waste plastic recycling plant

From washing basins for waste plastic to granule extruder, complete line of recycling plant can be seen on diagram. Recycling plant equipment is subject to change depending on polymer to be recycled. Recycling plants contain washing basins, crushing machine, agglomerator, drying unit, granule extruder and packaging unit.

Plastic recycling is recovery process of waste plastics and producing reusable raw material. Recycling of plastic starts by sorting waste material according to their resin types such as polyethylene, polypropylene, polystyrene, PET, PVC etc.

Clean plastic waste can be melted and converted into granules by using granule extruders. Before extruding, a size reduction or densifying process might be necessary. This can be done by using crushing machines or agglomeration machines.

Contaminated plastic material has to be washed and dryed first. For example plastic shopping bags which has been recovered from city waste has to be washed thoroughly before granulated. These shopping bags are made with high density polyethylene (HDPE) or low density polyethylene (LDPE). Agricultural films such as greenhouse covers (LDPE) also can be recycled.

The environmental benefits of recycling plastic are that it produces less waste and less carbon dioxide. Plastics are being used more and more nowadays. Disposing used plastics by land filling is a serious threat to environment. So recycling is only solution.

Recycled plastics can be used for producing trash bags, flower pots, park benches, industrial Pallets and pipes etc.

Recycled plastics can be used for producing trash bags, flower pots, park benches, industrial Pallets and pipes etc.

When you are inquiring recycling machinery, please

include plastic type, material state (film, lumber, crate, pipe etc.), contamination level (whether you require washing machines or not) and hourly capacity requirements. We look forward to answer your every kind of questions and inquiries regarding to plastic recycling.

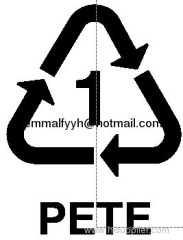

Code 1 and 2 Platics

- Code 1 plastics are known as PETE, or Polyethylene Terephthalate plastics, and are commonly used as water bottles, other plastic drink bottles, peanut butter containers and other food containers. Code 2 plastics are HDPE, or High-Density Polyethylene plastics, and are used to hold more stringent substances. Code 2 plastics are used in detergent containers, milk jugs and shampoo and juice bottles. It is thicker and more durable than Code 1 plastics.Code 1 and 2 plastics are the most common types picked up by curbside recycling. Call your local recycling center or municipal waste management department for information on signing up for recycling collection. Once signed up, dedicate a bin or bag in your house for code 1 and 2 plastics. Make sure the plastic containers are clean before recycling. Then simply place the plastics at curbside on collection day.

Code 3 Plastics

- Polyvinyl Chloride (PVC) is designated as Code 3. PVC is extremely durable and chemical resistant, and it is used in the plastic wrapping of meats, in pipes, blood bags and for insulation purposes. Code 3 plastics can be more difficult to recycle than types 1 and 2, but is still a commonly recycled plastic. Check with your recycling service to see if Code 3 plastics are accepted. If so, simply include code 3 plastics with type 1 and 2 plastics. If your recycling service does not accept these practices, ask for the location of a center that does. Then collect code 3 plastics until you have a significant amount -- this will cut down on trips -- and drop the plastics off at the recycling center.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Plastic Recycling Line

Recycling Line

Pet Recycling Line

Pe Recycling Line

Bottle Recycling Line

Film Recycling Line

More>>