|

Baoding Haorui Machinery Manufacturing Co., Ltd.

|

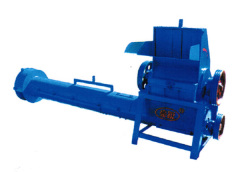

80 type shredder of waste PET bottle

| Payment Terms: | T/T,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The plastic crusher(also called plastic shredder) is used for shredding high volume bulk materials, products such as pallets, waste plastic, cardboard

The plastic crusher(also called plastic shredder) is used for shredding high volume bulk materials, products such as pallets, waste plastic, cardboard, furniture parts, and many other reusable materials.

We are an very experienced tire recycle machines, we can service for PET recycling machine, plastic recycling machine, recycled plastic machine, rubber recycling machine, powder grinder, plastic grinder, rubber powder manufacture.

Unique adjustment method for rotor and stator blades could double or even quadruple their life-span.

Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree.

Screen perforation is adjustable according to customer requirements.

The plastic crusher can be adjusted according to customer specific requirements for throughput volume, materials to be processed and so on.

The wasted plastic materials is shredded between the rotor knives and a fixed counter knife.

The screen hole with different perforation diameter determines the size of shreds. Produced shreds can drop from the machine through the screen perforation directly or be removed with the optional suction device or spiral conveyor.

Number 1 Plastics

PET or PETE (polyethylene terephthalate)

Found in: Soft drink, water and beer bottles; mouthwash bottles; peanut butter containers; salad dressing and vegetable oil containers; ovenable food trays.

Recycling: Picked up through most curbside recycling programs.

Recycled into: Polar fleece, fiber, tote bags, furniture, carpet, paneling, straps, (occasionally) new containers

PET or PETE (polyethylene terephthalate)

Found in: Soft drink, water and beer bottles; mouthwash bottles; peanut butter containers; salad dressing and vegetable oil containers; ovenable food trays.

Recycling: Picked up through most curbside recycling programs.

Recycled into: Polar fleece, fiber, tote bags, furniture, carpet, paneling, straps, (occasionally) new containers

PET plastic is the most common for single-use bottled beverages, because it is inexpensive, lightweight and easy to recycle. It poses low risk of leaching breakdown products. Recycling rates remain relatively low (around 20%), though the material is in high demand by remanufacturers

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!