|

Baoding Haorui Machinery Manufacturing Co., Ltd.

|

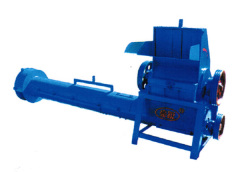

Plastic Crusher/Shredder Competitive Price

| Payment Terms: | T/T,L/C,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

These machines get a very high capacity and keeps maintenance costs low.

we is the legacy of more than 30 years manufacturing high speed shredders.

Description

Plastic Crusher Machine

Plastic Shredder Machine Specifications

1.Adopting deafener lower noise

2.Suitable for all kinds of plastic

3.Adopt removable blades can be separately

the waste plastic recycling shredder service access chamber open service.screw conveyor with the feed entrance.

According to the difference of the material, crushing squad can provide different rotor design, from strong grasp three chip to heavy cutting, semi-enclosed .

Plastic Shredder Machine Specifications

1.Adopting deafener lower noise

2.Suitable for all kinds of plastic

3.Adopt removable blades can be separately

the waste plastic recycling shredder service access chamber open service.screw conveyor with the feed entrance.

Crusher/shredder/pulverizer size:

machine type | Machine name | size | Blades quantity | Motor power | Machine capacity | Machine weight | ||||

length | width | height | Rotary blades | Stationery blades | ||||||

50 | Crusher/ shredder | 210cm | 180cm | 180cm | 3 | 2 | 18.5KW/25HP | 400kg/880lbs | 600kg | |

60 | Crusher/ shredder | 220cm | 180cm | 190cm | 3 | 2 | 18.5KW/25HP | 500kg/1100lbs | 650kg | |

80 | Crusher/ shredder | 220cm | 180cm | 240cm | 8 | 4 | 22KW/30HP | 800kg/1765lbs | 750kg | |

100 | Crusher/ shredder | 230cm | 180cm | 250cm | 8 | 4 | 37KW/50HP | 1500kg/3300lbs | 1500kg | |

120 | Crusher/ | 230cm | 190cm | 260cm | 10 | 4 | 45KW/61HP | 2000kg/4500lbs | 3000kg | |

Industrial Shredder,Plastic Crusher,plastic crushing machine,plastic grinder machinery

crusher are designed for use with strict requirements and not broken recycling material elaborate design generalheavy-duty crusher. High quality of GSC series crusher regardless of injection molded parts, shuikou material, body, profiles, pipes, film, sheet material or large solid body can be crushing. Equipment economy, practical, simple operation and durable.

According to the difference of the material, crushing squad can provide different rotor design, from strong grasp three chip to heavy cutting, semi-enclosed .

Features:

heavy-duty crusher can solve almost all plastic broken issues. Equipment economy practical, safe and convenient operation, high degree of automation.

rotor tool adopted the most advanced v-shaped cutting technology. V type cutting technology available in recycling process devastates for crushing material sent to rotating knife central, it avoids materials posted on wall, also increased a side wear resistance.

Crushing cabinet with the Central Line is bounded into fluctuation two parts, upside usable machinery device (or pneumatic device, hydraulic device) easy open, replace the cutter, safe and convenient maintenance. Sieve through the front door bolt and and machine upper apart.

rotor tool adopted the most advanced v-shaped cutting technology. V type cutting technology available in recycling process devastates for crushing material sent to rotating knife central, it avoids materials posted on wall, also increased a side wear resistance.

Crushing cabinet with the Central Line is bounded into fluctuation two parts, upside usable machinery device (or pneumatic device, hydraulic device) easy open, replace the cutter, safe and convenient maintenance. Sieve through the front door bolt and and machine upper apart.

Solid bearing device installed in machine exterior and independent of cutting chamber to prevent dust and dirt into the bearings. Prolong the service life of the machine while reducing the repair work. And crushing cavity separate independent bearing such an advantage for bringing water crushing particularly pronounced.

In order to improve the rotor axis of inertia, without driving square in the auxiliary installation fly-wheel.

All of the tool, including sword and the fixed knife, all can set in a cake layer of fixture adjustment, not again after a difficult inside machine adjustment tool process. Tool by high quality alloy steel, but heavy grinding times.

This series of machine can be set to join removable deflection wedge (3rd the fixed knife), can be used to change feeding mouth cross-sectional and required crusher cutting first cutting point.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Tyre Shredder Crusher

Plastic Shredder

Plastic Crusher

Plastic Crusher Machine

Plastic Strong Crusher

Shredder

More>>