|

Baoding Haorui Machinery Manufacturing Co., Ltd.

|

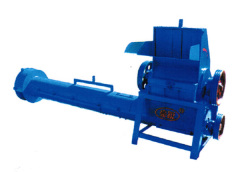

Model 100 tpyes berskala besar penghancur plastik

| Payment Terms: | T/T;Negotiable |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1 perkhidmatan akses ruang terbuka untuk perkhidmatan

2 skru memakan bahan-bahan

3.Motor adalah kelajuan tinggi, bunyi yang rendah

4 dengan fungsi

Model 100 tpyes large scale plastic crusher

1.Large scale crusher

1.Large scale crusher

2.Working for waste bottle

3.Motor is high speed,low noise

4 in stock nit available

5 feed screws sits on rails and retracts for easy access to crusher

6 provide service access chamber open for service

We can manufacture 100 tpyes of PET bottle crusher,competitive price.The bottle crusher enjoy long working time,Machine is easy operate,good washing result,it can bring you the perfect performance.

4 in stock nit available

5 feed screws sits on rails and retracts for easy access to crusher

6 provide service access chamber open for service

Crusher/shredder/pulverizer size:

machine type | Machine name | size | Blades quantity | Motor power | Machine capacity | Machine weight | ||||

length | width | height | Rotary blades | Stationery blades | ||||||

50 | Crusher/ shredder | 210cm | 180cm | 180cm | 3 | 2 | 18.5KW/25HP | 400kg/880lbs | 600kg | |

60 | Crusher/ shredder | 220cm | 180cm | 190cm | 3 | 2 | 18.5KW/25HP | 500kg/1100lbs | 650kg | |

80 | Crusher/ shredder | 220cm | 180cm | 240cm | 8 | 4 | 22KW/30HP | 800kg/1765lbs | 750kg | |

100 | Crusher/ shredder | 230cm | 180cm | 250cm | 8 | 4 | 37KW/50HP | 1500kg/3300lbs | 1500kg | |

120 | Crusher/ | 230cm | 190cm | 260cm | 10 | 4 | 45KW/61HP | 2000kg/4500lbs | 3000kg | |

The capacity can reached 3 tons per hours.

The crusher machine body made of heavy welded steel,it is looks like "clam-shell"structure,so,very easy to clean,also it is easy the change knives,to repair.Different rollers can applied to different materials.It is low noise,because it is equipped with noise-proof device.

Plastic shredders use For boxes, thin tube, blow molding parts, bottles, shells and other plastic recycling. Plastic shredders and convenient operation, simple and quick change blade, flat-type knife large thin-walled structure suitable for crushing large volume, thin material products to improve crushing efficiency; safe design with electronic control, the use of double hopper structure, filled insulation materials, motor with overload protection device, power supply has a good safety and environmental protection, energy saving and durable.

This machine has a low speed, low noise, fast cutting no slag. Wet grinding, in addition to the impact of the use of water to enhance the cleaning effect of the PET flakes, and because of the cooling effect of the water to reduce friction heat, extend tool life, low maintenance costs, long service life, the praise by the customers

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

100 Cotton Fabric

100 Wool Fabric

100 Cotton Shirt

100 Nylon Fabric

100 Cotton Blanket

100 Cotton Socks

More>>